As a result of this exciting merger, we are redirecting you to www.amcor.com where you can explore the expanded range of packaging solutions and innovative products that we now offer. For more information about this acquisition and to read the official press release, please visit: Read the Press Release

We look forward to continuing to serve our valued customers with enhanced capabilities and a broader portfolio of packaging solutions. Thank you for your ongoing support.

We provide a variety of products to meet a wide range of flexible packaging needs. Our in-house printing and converting capabilities ensure that we can support the evolving packaging needs of our customers.

Phoenix Flexible offers printed pouches with various structures & shapes to suit customers specific requirement. An ultra-modern pouching set up with laser scoring & fully automatic spouting machines ensure leak proof sealing & spouting for various viscous & challenging products.

The structure can be engineered with various options depending upon requirement of barrier properties, mechanical strength, finish, etc.

Stand Up Pouch With Doy Seal

Stand Up Pouch With Doy Seal  Stand Up Pouch With K Seal

Stand Up Pouch With K Seal  Shape Pouch

Shape Pouch  Spouted Pouch

Spouted Pouch  Quad Seal Pouch

Quad Seal Pouch  Gusset Pouch

Gusset Pouch  recyclable Pouch

recyclable Pouch  Add-ons. Hole Punches, Zippers,

Spouts & Other Options

Add-ons. Hole Punches, Zippers,

Spouts & Other Options Stand-up pouches stand up-right on the market shelves Thanks to its unique shape & ability to stand securely, that garb your customers’ attention.

They can be produced from practically any kind of non-barrier OR barrier material, making them suitable for the sterilisation and pasteurisation processes needed for soups and sauces. Chemical and high alcohol retaining products, such as disinfectants, handwash or screen wash are no problem.

We offer recyclable structure, laser score, different types of zip, handle, and valve application options.

K Seal Stand-up Pouch takes its name from the triangular sealed shape of the base with a sealing pattern similar to ‘K’. This K seal base construction makes the K-seal stand-up pouch a stable, upright packaging with good presentation properties. That’s why the K-seal is often used to pack bulk material and for larger volumes of liquid products, such as handwash, screenwash, etc.

They can be produced from practically any kind of non-barrier OR barrier material, making them suitable for the sterilisation and pasteurisation processes needed for soups and sauces. Chemical and high alcohol retaining products, such as disinfectants, handwash or screen wash are no problem.

We offer recyclable structure, laser score, different types of zip, handle, and valve application options.

With stand-up & conventional pouches getting common in market place, shapes are the new frontier for brands to differentiate from competition.

Shaped pouches helps to get excellent visual point of purchase impact. These bags not only hold you product but also can be used a marketing tool. Thanks to its shape which support the message, that you would like to give.

Pouches can be shaped & customized to match brand, function & appeal for a variety of packaging applications & markets.

They can be produced from practically any kind of non-barrier OR barrier material, making them suitable for the sterilisation and pasteurisation processes needed for soups and sauces. Chemical and high alcohol retaining products, such as disinfectants, handwash or screen wash are no problem.

We offer recyclable structure, laser score, different types of zip, handle, and valve application options.

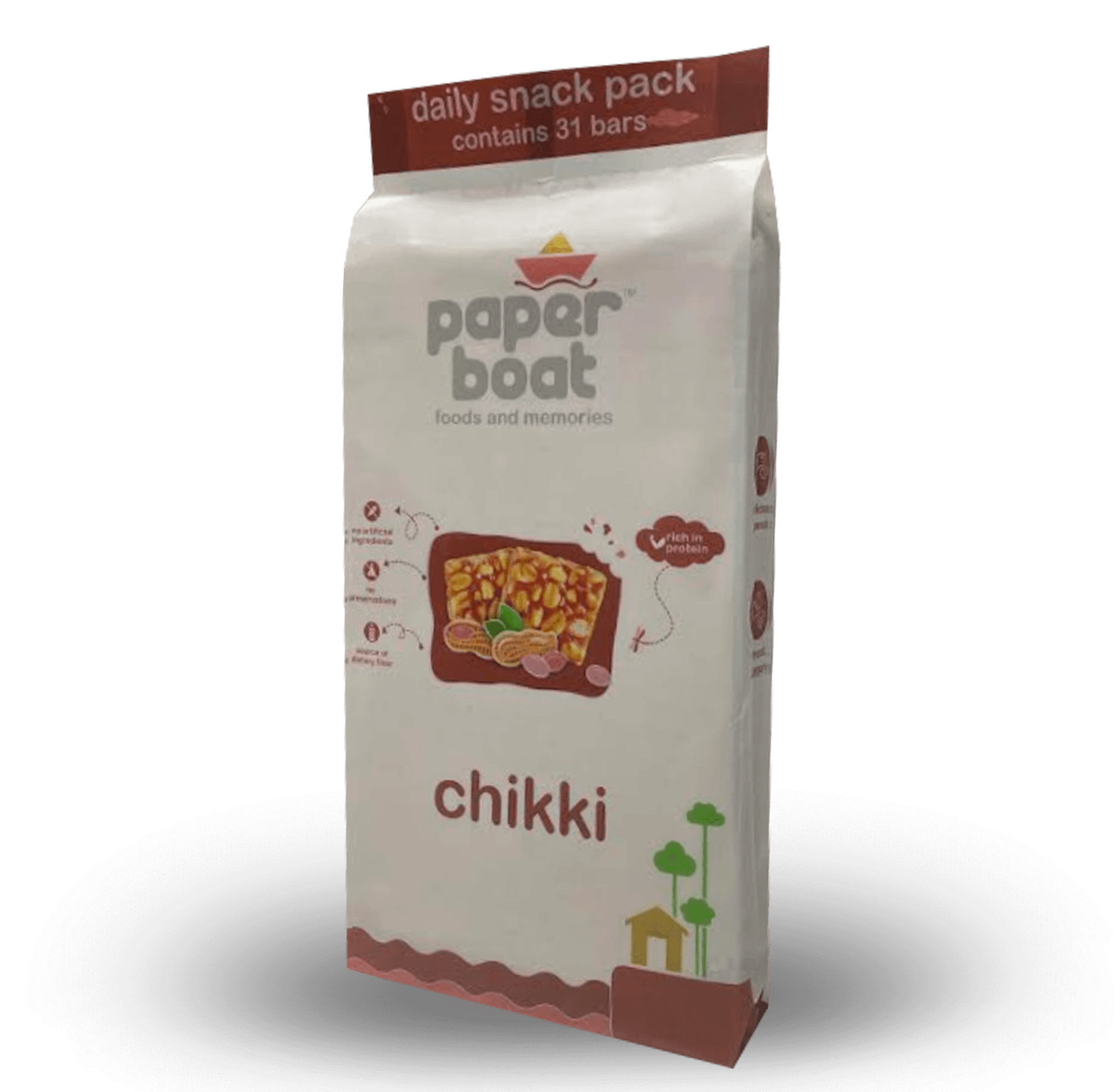

Spouted pouches guarantee the way to standout on retail shelves. Spout Pouch solutions offered by us are an attractive option for meeting the packaging demands of liquids with tamper evident & re closable spout cap making them ideal choice for refill packs.

Compared to PET or glass bottles, spout pouches are supplies takes minimum space resulting huge savings in packaging material & transportation. Once the pouches are filled they can easily be sorted into boxes or retail display cartons. Sturdy bottom gusset ensures, they remain in upright standing condition.

Pouches can be shaped & customized to match brand, function & appeal for a variety of packaging applications & markets.

Spout Pouches can be shaped & customized to match brand, function & appeal for a variety of packaging applications & markets

They can be produced from practically any kind of non-barrier OR barrier material, making them suitable for the sterilisation and pasteurisation processes needed for soups and sauces. Chemical and high alcohol retaining products, such as disinfectants, handwash or screen wash are no problem.

We offer recyclable structure, different types of spouts and handle.

Quad Seal pouches have four tucked in sides. When the four corners are sealed, we call this a Quad Seal OR Quadro Seal pouch. These seals give the packaging greater stability and a sleeker look. The strong construction makes both types of packaging suitable for packaging liquid and solid products. Filled with bulk products, these types of packaging remain upright.

As there is no back seal, all four panels maximise printing area & allowing front & back panel to be printed in full. The bag is heat sealed at the corners, with the seal only visible in the corners. This style is known for being robust, versatile and easy to handle in filling, handling and on the shelves.

Conventional multi-material pouches are non-recyclable.

Our Inhouse manufactured Ecolene range of MDO PE films enables 100% pouch recyclability, all containing the same type of polymer. This helps to produce flexible packaging that supports recyclability & the circular economy.

Multi-material flexible packaging is made of two or more materials laminated together by adhesive. Due to the multi-material structure, recycling of such films is not possible & usually end-of-life will be land-fil. Recyclability can be achieved by using mono-material flexible packaging, that uses one polymer only for different layers — most often Polyethylene.

Thanks to extensive research, MDO PE films can match transparency & stiffness of PET films, thereby converting PET/PE structure to recyclable PE/PE structure. recyclable films are seen as a major alternate for Sustainable Packaging & is being accepted by major Global FMCG companies.

Phoenix Flexibles will have an advantage as early entrant into MDO PE film offering through investment into Inline MDO PE Film Line from Hosokawa Alpine, Germany.

Globally, companies are working to convert their non-recyclable – multi material packaging structure into simple packaging structure with mono material, that can be 100 % recyclable. MDO PE Film will be used to replace PET film, thereby making laminate 100 % recyclable while retaining same gloss & stiffness.

Phoenix Flexibles offers range of sustainable packaging under following brand, which is registered by PFPL.

Side gusset bags and pouches creates rectangular space for the products once opened up. They usually take up less space on the shelf.

Side Gusset Pouches are the most popular pouches for coffee and tea & can be supplied with one way degassing valve. These side gusset pouches maximises the storage capacity since they square out after being filled. They have gussets on both sides and an inclusive fin-seal runs from top to bottom with horizontal sealing at both the top-side and the bottom-side. The top-side is usually left open for filling the products, which is normally powder or small granular like tea, coffee, rice, lentils, etc.

Side gusset bags and pouches creates rectangular space for the products once opened up. They usually take up less space on the shelf.

Side Gusset Pouches are the most popular pouches for coffee and tea & can be supplied with one way degassing valve. These side gusset pouches maximises the storage capacity since they square out after being filled. They have gussets on both sides and an inclusive fin-seal runs from top to bottom with horizontal sealing at both the top-side and the bottom-side. The top-side is usually left open for filling the products, which is normally powder or small granular like tea, coffee, rice, lentils, etc.